My Article For United States Faceting Guild

Getting to know the Gemstone Industry from Around the World article written in the https://usfacetersguild.org/

Dennis Williamson of Scotia Lapidary in Scotland

My interest in lapidary began in childhood when my grandfather would take our entire family, including my dad and all his brothers, to explore an abandoned coastal marble quarry. Among the “treasures” we discovered were serpentine marble pieces banded with beautiful reds and greens, occasionally we would find an eye clean quartz crystal.

Together, we would shape these stones using emery paper and polish them with 'Tcut' car paint polishing compound.

One of my fondest memories from those days was creating a favourite piece that followed the natural colour bands in the marble, resembling a hound dog with a smiling mouth. These early experiences sparked my lifelong passion for lapidary.

This childhood seed planted by my grandfather in rockhounding and Lapidary, stayed inside me waiting for an opportunity germinate, until COVID hit the world, and it felt like the human race might end. That’s when my seed started to grow.

One peculiarity about me is my inclination to tackle tasks at a heightened pace. My mind operates like a computer with multiple windows open simultaneously, constantly processing various scenarios and problems. Recently, I discovered through a university course that I have ADHD and several other neurodiverse conditions. When the COVID-19 pandemic forced me to stay home, I felt confined, like a cat in a cage.

To combat this feeling of confinement, I turned to the internet as my gateway to the outside world. I immersed myself in YouTube videos created by gem cutters worldwide and attended online seminars hosted by industry experts such as Justin K. Prim, Vincent Pardieu, and the GIA. Eager to embark on my gem cutting journey, I imported my first faceting machine from Sterling Gems in Sri Lanka and retreated to my attic to dedicate eight hours a day to learning the craft.

Drawing from my background as a lecturer at a local technical college, I devised a self-imposed apprenticeship plan. In my first year, I focused on cutting and polishing synthetic materials before progressing to lower grade natural materials in my second year and higher-grade natural materials in my third year. This structured approach allowed me to gradually refine my skills and gain proficiency in gem cutting.

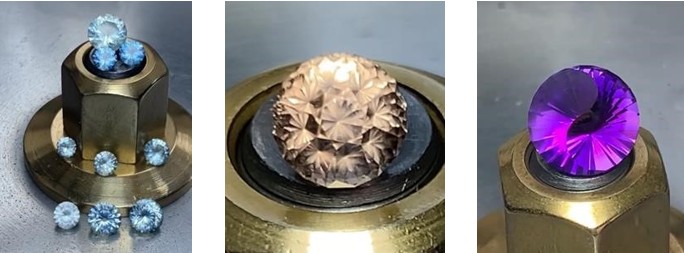

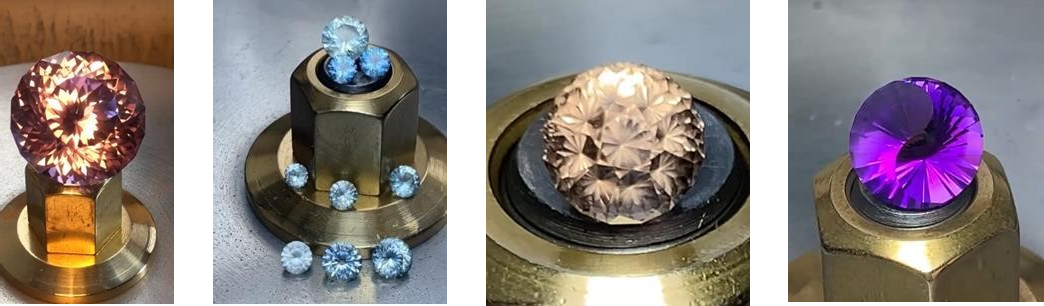

Stones I cut early in my cutting journey. Starting on the left a massive YAG from Russia, Aquamarine from Pakistan, Natural topaz, and natural Amethyst.

Finding gem rough material poses a significant challenge for any gem cutter, and 'buyer beware' should be the mantra for newcomers to gem cutting. I invested in diagnostic tools and diligently studied their usage, alongside reading books to enhance my knowledge. Despite these efforts, I soon found myself with a collection of genuine certified rough stones, now weathered in my garden—a testament to the lessons learned the hard way.

Over time, I've developed a preference for purchasing from a select few sellers in Pakistan, whom I trust and buy from regularly. Nonetheless, I remain vigilant against the abundance of fake rough on the market, particularly those offered in preform shape and uniform colours at seemingly too-good to-be-true prices. It's a reminder to exercise caution and discernment, as some sellers are quick to exploit inexperienced buyers for a quick profit.

In Scotland, acquiring faceting equipment, including machines, laps, polish, dops, and jigs, presents a significant challenge, unlike in other parts of the world where such equipment is readily available through in-person or mail-order channels.

Upon reaching a certain level of proficiency in my gem-cutting apprenticeship, I recognized the need for a more repeatable faceting machine. Consequently, I purchased a 50-year-old Imahashi machine for £2000 on eBay. This acquisition demonstrated the reality that aspiring gem cutters in the UK must possess the skills to repair and maintain their equipment, and at times, even construct their own equipment from scratch.

For the past two years, I've relied on this 50-year-old Imahashi machine for my daily gem-cutting endeavours. Becoming accustomed to its slowest speed pulley setting, I've honed my technique through consistent practice. Over time, I've crafted some truly remarkable stones, and my skills have steadily improved day by day.

I have renovated a few faceting machines now, with the latest one being a sorely abused Omni from Jersey instruments.

This may tempt me towards at least trying mast machine cutting, I suppose it’s much like the car you learned on, stick shift, or automatic, it imprints on you what you drive.

One thing I love to do, not only in my day job, but also in the faceting and jewellery world is to teach others.

Last year, I began teaching jewellers free of charge. While I don't charge for my time, the use of my handpiece machines, or gem materials, the experience has been immensely rewarding. I've had the pleasure of meeting creative, like-minded individuals from around the world who have come to Scotland to learn smithing and jewellery making. As I've continued to deliver more lessons, I've honed my teaching technique and created visual aids to enhance students' understanding of the gem cutting process.

One of the lessons I've developed is aimed at helping jewellers gain a deeper understanding of what constitutes a well-cut gemstone, including its proportions and identifying flaws that may affect its setting. Collaborating with students to cut stones together adds to the enriching experience.

Meeting and collaborating with jewellers have afforded me the opportunity to see stones transformed into exquisite pieces of jewellery. And working with creative individuals in the jewellery industry has provided me with unexpected opportunities to explore unique concepts. For instance, I was once asked to facet

A piece of sentimental sea glass to be incorporated into a piece of jewellery, a request that sparked my imagination in ways I hadn't previously considered.

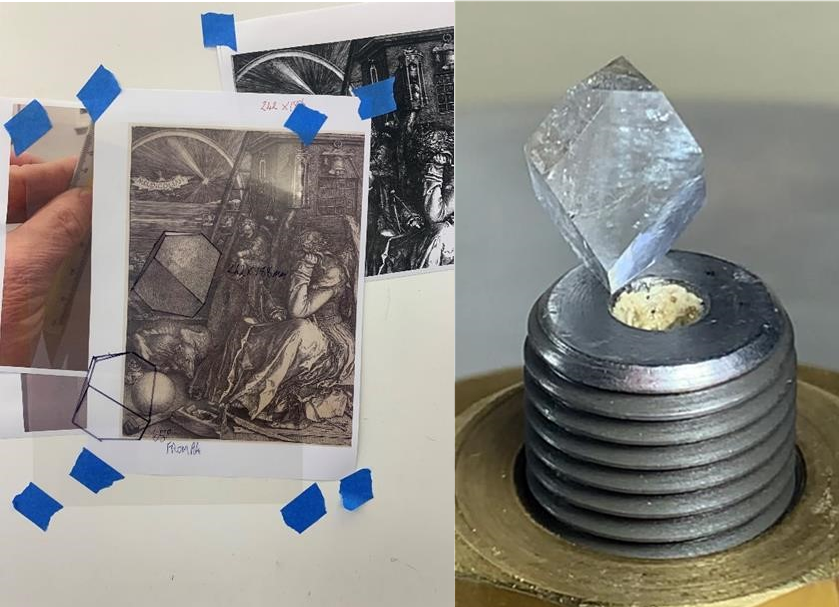

I received an imaginative request from a jeweller based in Scotland to replicate the solid from Albrecht Durer’s engraving Melancholia 1. With the assistance of Steven Miles, Wahid Mottaghian, and my drawing board in the office, I meticulously cut several replicas in various materials and angles. These pieces will serve as the foundation for an entry that the jeweller plans to incorporate into a custom-designed ring, aiming to secure a scholarship.

I use sintered laps for all my cutting. My go to ones are made in Latvia, Ukraine, and Russia. For my students’ cutting laps I use resin sintered laps made in China. And the students facet on Sri Lankan hand piece machines. My go to pre polish lap for all stones is the BATT lap from Gearloose on 3k crayon diamond. For polishing quartz, I use Diamatrix and cerium from Gearloose. For all other stones I polish on a Tin+ from Gearloose or a Corian lap — both laps using Gearloose diamond — either 60 or 100k.

I enjoy challenging myself to cut increasingly intricate designs, which may be better suited for a mast machine with precise 10th-degree increments on the protractor. However, I'm proud of the results I achieve using my decades-old analogue Imahashi hand piece machine. You can see my cutting on Facebook here.

Gem cutting isn't just a craft; it's an art form with limitless possibilities. From cutting intricate designs to experimenting with unconventional materials like sea glass, each project pushes me to explore new creative horizons.

Despite being partway through my gem cutting journey, I am continually amazed by the depth and breadth of this craft. With each stone cut and each lesson taught, I am reminded of the boundless creativity and camaraderie within the global gem cutting community.

As I continue to grow as a gem cutter and educator, I am grateful for the support and generosity of this worldwide community. With every facet polished and every lesson learned, I look forward to the endless possibilities that lie ahead.

Best wishes from Scotland

Dennis Williamson

Scotia Lapidary

I am also a member of the:

All photos by the author.